Unlock the Secrets of Vapor Tight LED Retrofits: Transform Your Wet Spaces Today!

In today's world, ensuring the safety and efficiency of lighting solutions in wet locations is more critical than ever. Vapor tight LED retrofits are revolutionizing the way we illuminate these challenging environments. Whether it's a commercial kitchen, a car wash, or an outdoor area exposed to the elements, these specialized lighting fixtures provide the durability and performance required to withstand moisture and humidity. In this article, we’ll delve deep into the world of vapor tight LED retrofit solutions for wet locations, exploring their design, benefits, installation processes, and the compliance standards that guide their use. By the end, you’ll have a comprehensive understanding of why these retrofits are essential for anyone looking to enhance their wet spaces.

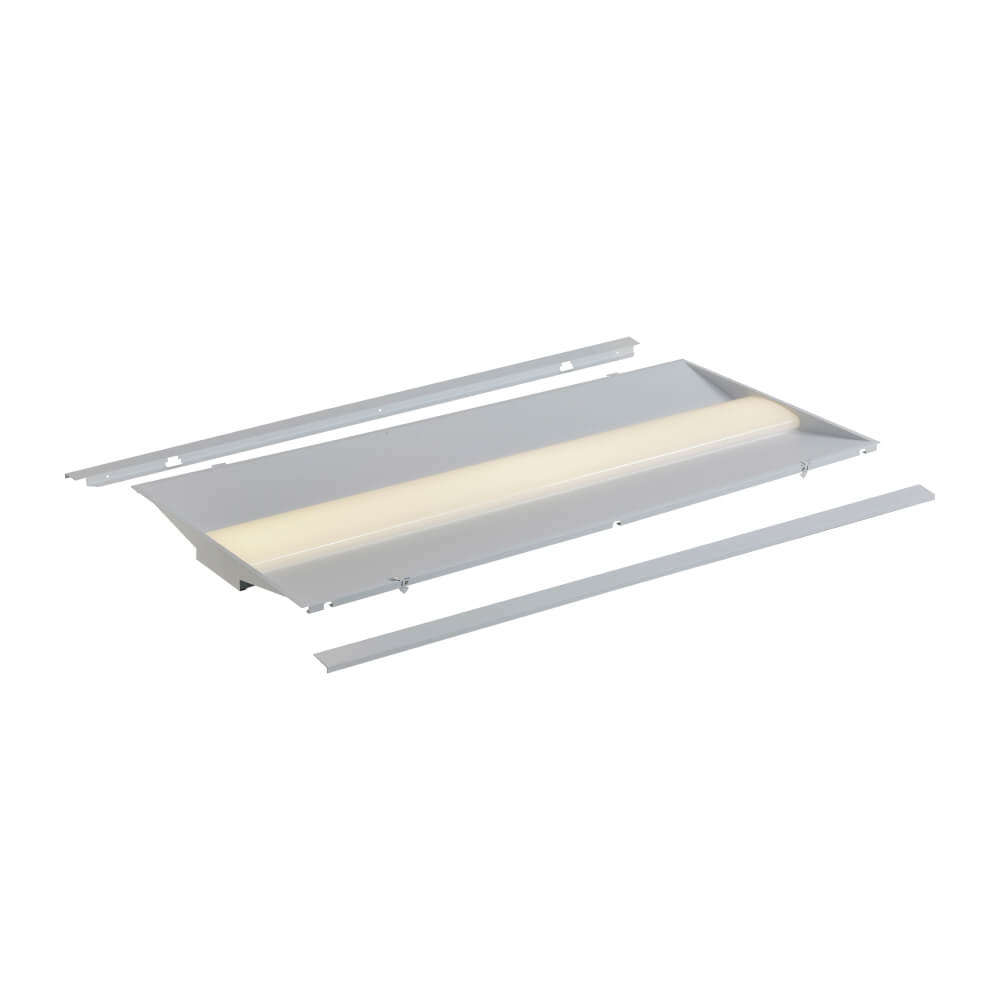

Understanding Vapor Tight LED Retrofits

Vapor tight LED retrofits are specially designed lighting solutions that replace traditional fluorescent or incandescent bulbs in wet locations. The term "vapor tight" refers to the unique construction of these fixtures, which includes sealed enclosures that prevent moisture, dust, and debris from entering. This design is crucial in environments such as outdoor storage facilities, food processing plants, or wash-down areas, where exposure to water is frequent. The functionality of vapor tight LED retrofits extends beyond mere protection; they also offer significant improvements in energy efficiency and lifespan compared to their predecessors. As a result, they not only provide reliable illumination but also contribute to a more sustainable approach to lighting.

Benefits of Vapor Tight LED Retrofits for Wet Locations

One of the standout advantages of vapor tight LED retrofits is their energy efficiency. These LEDs consume significantly less power than traditional lighting options, which translates to lower electricity bills and a reduced carbon footprint. Additionally, vapor tight LEDs are designed to last longer, often exceeding 50,000 hours of usage. This longevity means fewer replacements, resulting in further cost savings over time. Another critical benefit is enhanced safety; the sealed design reduces the risk of electrical hazards in wet environments. A friend of mine recently renovated their commercial kitchen with vapor tight LEDs, and they reported not only improved visibility but also a noticeable decrease in energy costs. Overall, integrating these retrofits into wet locations can lead to substantial long-term benefits.

Installation Process for Vapor Tight LED Retrofits

Installing vapor tight LED retrofits can be a straightforward process if approached methodically. First, gather the necessary tools, including screwdrivers, wire strippers, and safety gear such as gloves and goggles. Begin by turning off the power to the existing fixtures to ensure safety during the installation. Remove the old lighting fixture and disconnect the wiring. Next, prepare the vapor tight LED retrofit by connecting the new fixture's wires to the electrical supply, ensuring to match the colors correctly – typically black to black (live), white to white (neutral), and green or bare to ground. Once secured, mount the new fixture to the ceiling or wall using appropriate hardware. It’s essential to check for proper sealing after installation to maintain the vapor tight integrity. Common challenges may include navigating existing wiring or dealing with a lack of space in tight locations, but careful planning and patience can help overcome these hurdles. As a handy tip, having a friend assist can make the installation process smoother and quicker.

Compliance Standards and Regulations

When it comes to lighting in wet locations, compliance with safety standards is paramount. Organizations such as the National Electrical Code (NEC) and Underwriters Laboratories (UL) set forth regulations that govern the installation and usage of lighting fixtures in hazardous environments. Vapor tight LED retrofits are designed to meet or exceed these standards, ensuring they are safe for use in wet conditions. For instance, many fixtures are rated for both IP65 and IP66, indicating their level of protection against water and dust ingress. Before making a purchase, it is crucial to verify that the chosen retrofit complies with local regulations and standards to avoid potential hazards and ensure a safe environment. Knowledge of these compliance standards can not only safeguard your investment but also provide peace of mind when utilizing lighting solutions in wet locations.

Enhancing Wet Location Lighting with Retrofits

In conclusion, vapor tight LED retrofits present an excellent solution for enhancing lighting in wet locations. From their robust design and energy efficiency to their compliance with safety standards, these retrofits address the unique challenges posed by moisture-prone environments. The benefits of reduced energy costs and increased safety make them a worthwhile investment for both residential and commercial spaces. As you consider options for illuminating your wet areas, remember the advantages that vapor tight LED retrofits provide. With the right knowledge and preparation, transforming your spaces with these innovative lighting solutions is within reach.