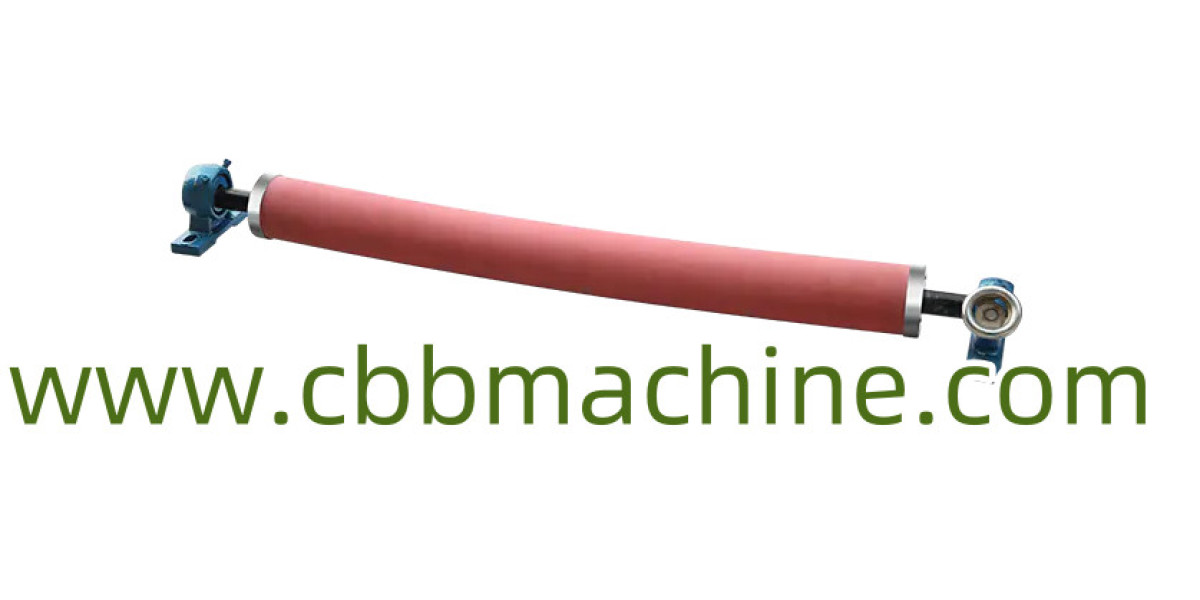

Why Choosing the Right Banana Rollers Supplier Matters for Your Production Line

A dependable Banana Roller supplier plays a crucial role in helping manufacturers maintain high production efficiency, particularly when working with delicate or flexible web materials. Banana rollers, often referred to as bowed rollers or curved rollers, are widely used in industries such as printing, film production, textile processing, packaging, and more. Their main function is to spread and straighten material as it moves through various stages of production, preventing wrinkles, misalignment, and uneven tension.

When selecting banana rollers for your equipment setup, customization and quality manufacturing are key factors. These rollers are not one-size-fits-all; they must be tailored to specific parameters, such as web width, tension, line speed, material thickness, and environmental conditions. That’s why partnering with an experienced Banana Rollers supplier can have a direct impact on the performance of your production system.

Banana rollers are designed to reduce slack and smooth out web material using a precise curved profile. This curvature helps distribute tension evenly across the web’s width, avoiding issues such as folds or bubbles. For processes involving thin plastic films, paper, laminates, or textile sheets, even a slight distortion can lead to product defects or machine stoppages. High-quality banana rollers are engineered with a calculated bow angle and supported by dynamic balancing to minimize vibration and wear.

Working with a specialized Banana Rollers supplier ensures access to a variety of materials and structural options to match your operational needs. For example, roller cores may be manufactured from lightweight aluminum to reduce inertia in high-speed applications or from stainless steel for added durability in harsh or corrosive environments. The choice of roller covering—such as rubber, PU, or chrome plating—can also be adapted to provide extra grip or protection depending on the nature of the web material.

Another key consideration is how the roller is mounted and driven. Banana rollers can be fixed or adjustable, depending on whether the bow angle needs to change for different production batches. Some rollers are designed to rotate freely, while others integrate with drive systems for active tension control. Choosing the right setup often requires detailed technical consultation, which a knowledgeable Banana Rollers supplier should be able to offer.

Maintenance and lifespan are additional reasons to invest in quality rollers. A poorly manufactured roller may show signs of imbalance, surface wear, or bearing failure after only a short time in use. This can result in unplanned downtime and higher replacement costs. In contrast, banana rollers with precision machining and high-grade components offer smoother operation, reduced vibration, and longer service intervals. A trustworthy supplier will provide quality assurance and technical documentation, making integration and servicing much easier for your team.

For manufacturing companies looking to improve sustainability and energy efficiency, modern banana rollers are often engineered for reduced weight and friction. Lower mass helps minimize motor load, which can reduce energy consumption. At the same time, smoother rotation and better bearing quality lead to less heat generation and reduced noise during operation.

In summary, a reliable Banana Rollers supplier is more than just a source for components—they are a valuable partner in optimizing machine efficiency, improving product quality, and reducing operating costs. Whether you're upgrading an existing line or setting up a new one, investing in tailored banana rollers can contribute to smoother, more consistent production outcomes across the board.