Operational sound exposure has become a defining concern within modern maritime operations. Commercial fleets and naval platforms alike operate under demanding acoustic conditions driven by propulsion assemblies, auxiliary generators, ventilation networks, and mission-critical machinery. Within the first stages of vessel planning and lifecycle servicing, Marine Noise Insulation is now treated as a structural requirement rather than a discretionary enhancement. When operators evaluate long-term upkeep options such as Boat maintenance near me, noise mitigation strategies are increasingly bundled into performance and compliance reviews.

Strategic Importance of Acoustic Regulation at Sea

Persistent vibration and airborne resonance within enclosed marine environments directly influence crew endurance, communication accuracy, and system reliability. Elevated decibel accumulation can accelerate material fatigue and compromise sensitive electronic instrumentation. For naval deployments, acoustic discretion also carries tactical implications, affecting detectability and mission integrity.

High-performance Marine Noise Insulation frameworks are engineered to suppress both structure-borne and airborne transmission. Unlike conventional padding materials, these systems utilize composite layering, constrained damping technologies, and frequency-specific attenuation profiles tailored to vessel classification and operational tempo.

Material Science Behind Advanced Marine Noise Control

Specialized Composite Barriers

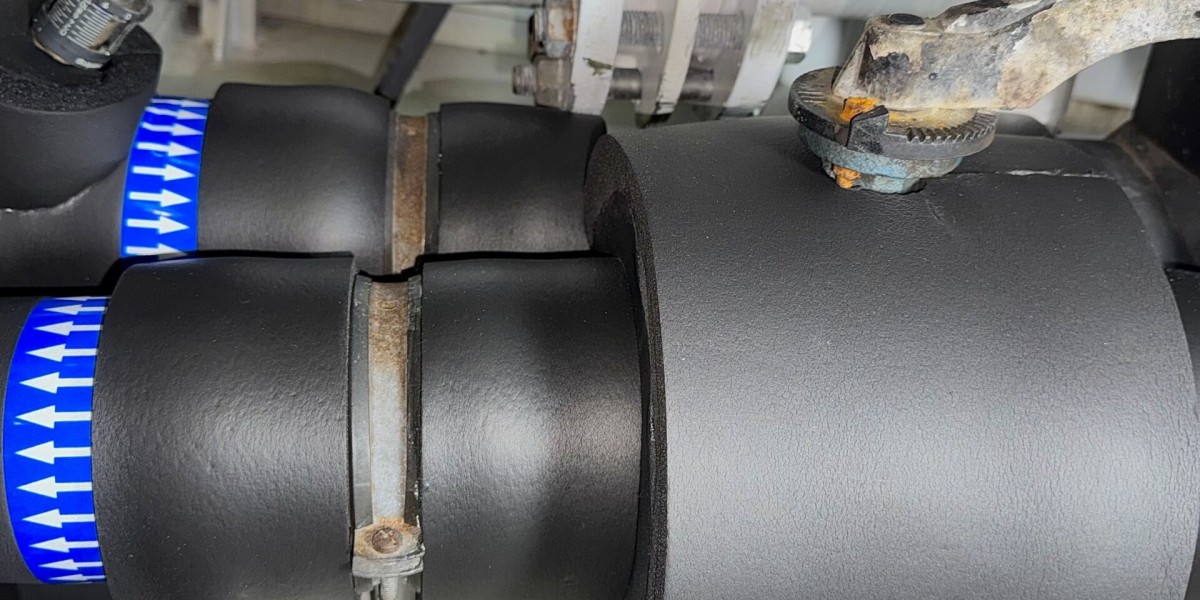

Modern insulation assemblies rely on multilayer composites combining mass-loaded membranes, viscoelastic cores, and corrosion-resistant surface facings. These barriers are optimized for maritime exposure, tolerating salinity, thermal variation, and prolonged mechanical stress without acoustic degradation.

Through calculated impedance mismatching, these materials disrupt sound wave propagation across bulkheads, decks, and machinery enclosures. This approach ensures consistent attenuation across low-frequency engine harmonics and higher-frequency auxiliary emissions.

Fire-Resistant and Regulatory-Aligned Design

Commercial and naval standards mandate strict adherence to flame spread, smoke density, and toxicity thresholds. High-grade Marine Noise Insulation systems are formulated to meet international maritime safety codes while maintaining acoustic efficacy. Integration with fire-rated partitions allows insulation to perform dual roles without spatial penalties.

Application Zones Within Commercial and Naval Platforms

Engine Rooms and Propulsion Compartments

Primary machinery spaces represent the most aggressive acoustic environments aboard any vessel. Insulation packages installed here are designed for extreme decibel suppression and vibration damping. Precision-cut panels, flexible blankets, and vibration isolators collectively reduce transmitted noise into adjacent living or command areas.

Routine inspections tied to Boat maintenance near me services frequently identify these compartments as priority zones for insulation upgrades due to cumulative wear and evolving compliance benchmarks.

Crew Accommodation and Operational Centers

Habitability directly affects personnel effectiveness during extended deployments. Acoustic treatments within berthing areas, mess facilities, and operational command rooms are calibrated to create controlled soundscapes. This enables restorative rest cycles and uninterrupted decision-making, even during high-load operational periods.

Installation Methodologies and Lifecycle Considerations

Modular Retrofitting Solutions

One of the defining advantages of contemporary Marine Noise Insulation is modular adaptability. Pre-engineered panels and encapsulation systems allow rapid retrofitting during scheduled dock intervals. This minimizes vessel downtime and aligns insulation upgrades with broader maintenance workflows, including searches for Boat maintenance near me providers.

Durability and Performance Longevity

Unlike legacy insulation products that compress or delaminate over time, high-performance systems maintain acoustic integrity throughout extended service cycles. Anti-wicking surfaces prevent moisture ingress, while reinforced cores resist mechanical deformation. This durability reduces replacement frequency and stabilizes lifecycle cost projections.

Acoustic Compliance and Operational Risk Reduction

International maritime authorities continue to tighten occupational noise exposure limits. Failure to comply exposes operators to regulatory penalties, crew health liabilities, and reputational risk. Advanced Marine Noise Insulation functions as a proactive compliance mechanism, enabling vessels to meet evolving thresholds without structural redesign.

For naval assets, reduced onboard noise also enhances sonar clarity and internal communication reliability, contributing indirectly to operational superiority.

Integration With Predictive Maintenance Programs

Modern fleet management increasingly leverages predictive diagnostics. Acoustic insulation performance data can now be incorporated into these models, allowing operators to anticipate degradation before thresholds are breached. When maintenance teams coordinate upgrades through Boat maintenance near me channels, insulation assessments are often synchronized with vibration analysis and thermal mapping.

This integrated approach transforms Marine Noise Insulation from a passive component into an active contributor to asset intelligence.

Environmental and Efficiency Implications

Effective acoustic containment also influences thermal efficiency. Insulation layers that suppress sound frequently provide auxiliary thermal resistance, stabilizing machinery operating temperatures. This reduces cooling demand, lowers fuel consumption, and contributes to emission reduction targets increasingly mandated across commercial shipping sectors.

Naval planners similarly value insulation systems that deliver multifunctional performance without increasing displacement or compromising mission flexibility.

Future Trajectory of Marine Acoustic Engineering

Research initiatives are advancing toward adaptive insulation materials capable of dynamic frequency response. These innovations promise real-time noise modulation based on operational mode, further refining onboard acoustic environments. As these technologies mature, Marine Noise Insulation will continue to redefine baseline expectations for vessel design and maintenance planning.

Conclusion

High-performance acoustic solutions have become inseparable from modern maritime engineering strategy. By embedding Marine Noise Insulation into vessel construction, retrofitting, and routine servicing cycles such as Boat maintenance near me programs, operators achieve measurable gains in safety, efficiency, and operational resilience. As regulatory pressure and performance expectations intensify, investment in advanced noise control systems remains a decisive factor in sustaining commercial viability and naval readiness.