The global thermal spray coatings market size was estimated at USD 10.46 billion in 2023 and is expected to grow at a CAGR of 4.8% from 2024 to 2030. The thermal spray coatings market growth depends on their use in various end-use industries like automotive, aerospace, medical, industrial gas turbine, printing, steel, and pulp & paper. The rising use of gas turbines in helicopter engines, tanks, ships, and locomotives is expected to help augment the demand for thermal spray coatings due to their high temperature and corrosion resistance, which protects the parts against fire in high-temperature and moisture-laden conditions.

The properties provided by thermal spray coatings include wear resistance against abrasion, cavitation, and erosive forces, chemical resistance, electrical insulation, and better adhesion between the substrate and top layer of components. The stringent regulations by the U.S. EPA, REACH, and OSHA regarding the curtailment of hard chrome plating, which produces a byproduct recognized as a carcinogen, influence the coating manufacturers to adopt sustainable solutions that can further propel the market growth in various end-use industries. In North America, the U.S. accounted for the largest share of the regional market in 2021.

Gather more insights about the market drivers, restrains and growth of the Global Thermal Spray Coatings Market

Detailed Segmentation:

Material Insights

Ceramics material segment dominated the market with a revenue share of over 31.0% in 2023. This is attributed to the fact that ceramic coatings have excellent adhesion properties, which help them adhere to the surface and provide corrosion protection, thermal barrier, dielectric strength, and sliding wear resistance to the coated materials. Due to the thermal barrier property, ceramics are often utilized in heat insulation applications to improve the operational efficiency of components in high-temperature environments and extend the service lifespan of components. Abradable materials tend to wear when rubbed against a highly abrasive material while protecting the underlying material and leaving it damage-free. It is used for coating gas turbine engines for clearance control, which helps prevent the change in dimensions that occur due to thermal expansion since the rotating assemblies and blades heat up and cool down during operation.

Technology Insights

Plasma spray technology segment dominated the market with a revenue share of over 32.0% in 2023. This is attributed that this process provides the advantage of spraying metallic and ceramic materials onto various surfaces with excellent bond strength while minimizing substrate distortion on both large and small components offering. It provides electrical conductivity, clearance control, wear resistance, and heat & oxidation resistance to the substrate surface. The plasma thermal spray coatings process is used on printing rolls, gas turbines, industrial diesel engine piston rings, and oil & gas machinery. Moreover, this process is adopted widely in coating orthopedic and dental implants due to its ability to produce a dense and porous surface layer, surface roughness, and microstructure of the coatings depending upon the requirement.

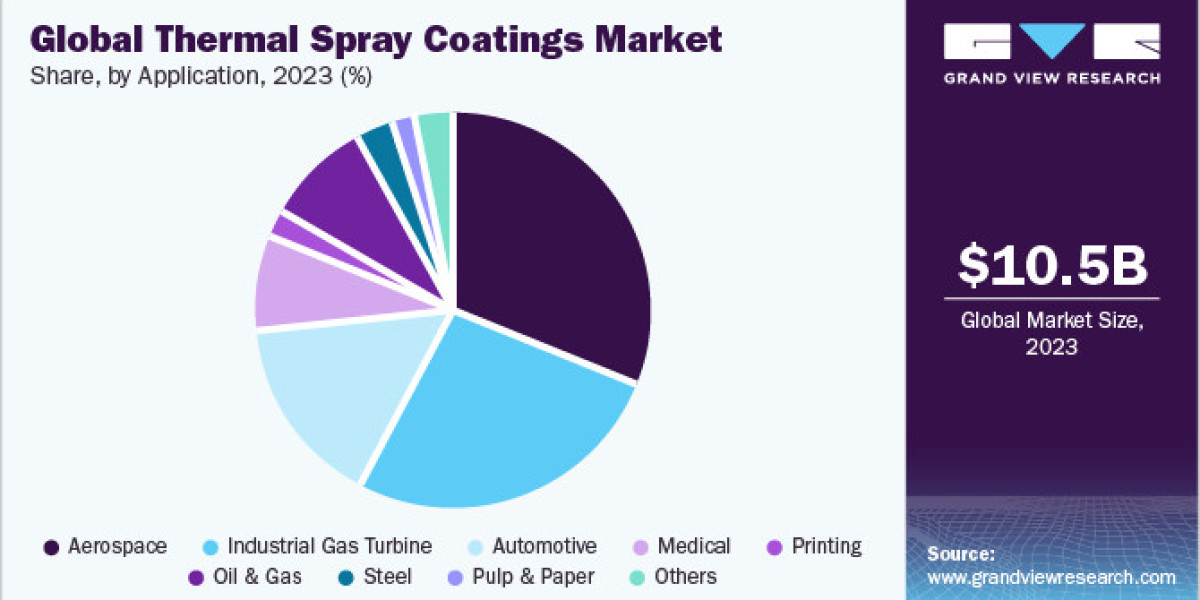

Application Insights

Aerospace in the application segment dominated the market with a revenue share of over 32.0% in 2023. This is attributed to the high product demand in aerospace applications as parts in an aircraft are prone to degradation owing to particle erosion, hot corrosion, metal-to-metal wear, and fretting. According to a report published by Deloitte in 2021, due to the pandemic-induced impact on customer demand and pricing pressure, many aerospace manufacturers are seeking new aftermarket services revenue opportunities. This is expected to increase the Maintenance, Repair, and Overhaul (MRO) work, which can boost product demand in aerospace applications.

Browse through Grand View Research's Bulk Chemicals Industry Research Reports.

- Food Grade Alcohol Market: The global food grade alcohol market size was valued at USD 3.50 billion in 2023 and is projected to grow at a CAGR of 2.9% from 2024 to 2030.

- Offshore Mooring Systems Market: The global offshore mooring systems market size was valued at USD 1.56 billion in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

Regional Insights

North America dominated the market with a revenue share of 28.6% in 2022 due to the high product demand in key industries in the region, including aerospace, oil & gas, automotive, medical, and power generation. Moreover, the governments in the U.S. and Canada are funding projects to develop innovative coatings that can act as a driving factor for market growth. For instance, in February 2022, the Government of Canada announced to provide USD 18.92 million (CAD 24 million) through the New Frontiers in Research Fund for a project to develop unique molecular coatings that could save maintenance costs across sectors including healthcare, infrastructure, automotive, aerospace, and consumer electronics.

Key Companies & Market Share Insights

Some of the key players operating in the market include Cincinnati Thermal Spray, Inc., Höganäs AB, and 4 H.C. Starck, Inc. among others.

- Cincinnati Thermal Spray, Inc., offers various types of products, including wear & corrosion, friction engineering, corrosion resistance, thermal protection, and electrical coatings.

- Höganäs AB operates through several subsidiaries, namely Höganäs Japan K.K, Höganäs HOGAP AB, Höganäs France S.A.S, Höganäs East Europe LLC, North American Höganäs Holdings Inc., and Höganäs Italia S.r.I and is engaged in the manufacturing of thermal spray coatings.

- C. Starck Inc. is engaged in the production of refractory metals, thermal spray powder, high-performance ceramics, niobium & rhenium, tantalum, molybdenum, and tungsten

- Medicoat AG, Praxair Surface Technologies, Inc. and Precision Coatings, Inc. are some of the emerging market participants in the specialty chemicals market.

- Medicoat AG provides coating systems and spray coatings for the medical sector. It offers optimized medical coatings that comply with the ISO standards and ASTM requirements.

- Praxair Surface Technologies, Inc. is engaged in the production and distribution of surface-enhancing materials and offers ceramic and metallic coatings to address problems such as oxidation, high temperature, galling, erosion, corrosion, and abrasion.

Key Thermal Spray Coatings Companies:

- Praxair Surface Technologies, Inc.

- Höganäs AB

- C. Starck Inc.

- Castolin Eutectic

- Wall Colmonoy Corp.

- Powder Alloy Corp.

- Saint-Gobain S.A.

- Carpenter Technology Corp.

- Fujimi Incorporated

- Durum Verschleiss-Schutz GmbH

- Montreal Carbide Co. Ltd

- Kennametal Stellite

- Oerlikon Metco

- GTV Verschleißschutz GmbH (GTV Weat Protection GmbH)

Order a free sample PDF of the Thermal Spray Coatings Market Intelligence Study, published by Grand View Research.