When it comes to lighting in food processing plants, the choice of illumination is crucial for both safety and efficiency. High-efficiency vapor tight LED lighting has emerged as an essential component in these facilities, offering a range of benefits that traditional lighting solutions cannot match.

The Importance of Lighting in Food Processing Plants

Food processing plants require lighting that not only provides adequate visibility for workers but also complies with strict hygiene and safety regulations. In these environments, where food products are handled and processed, the right lighting can make a significant difference in maintaining cleanliness and preventing contamination.

Why High-Efficiency Vapor Tight LED Lighting Stands Out

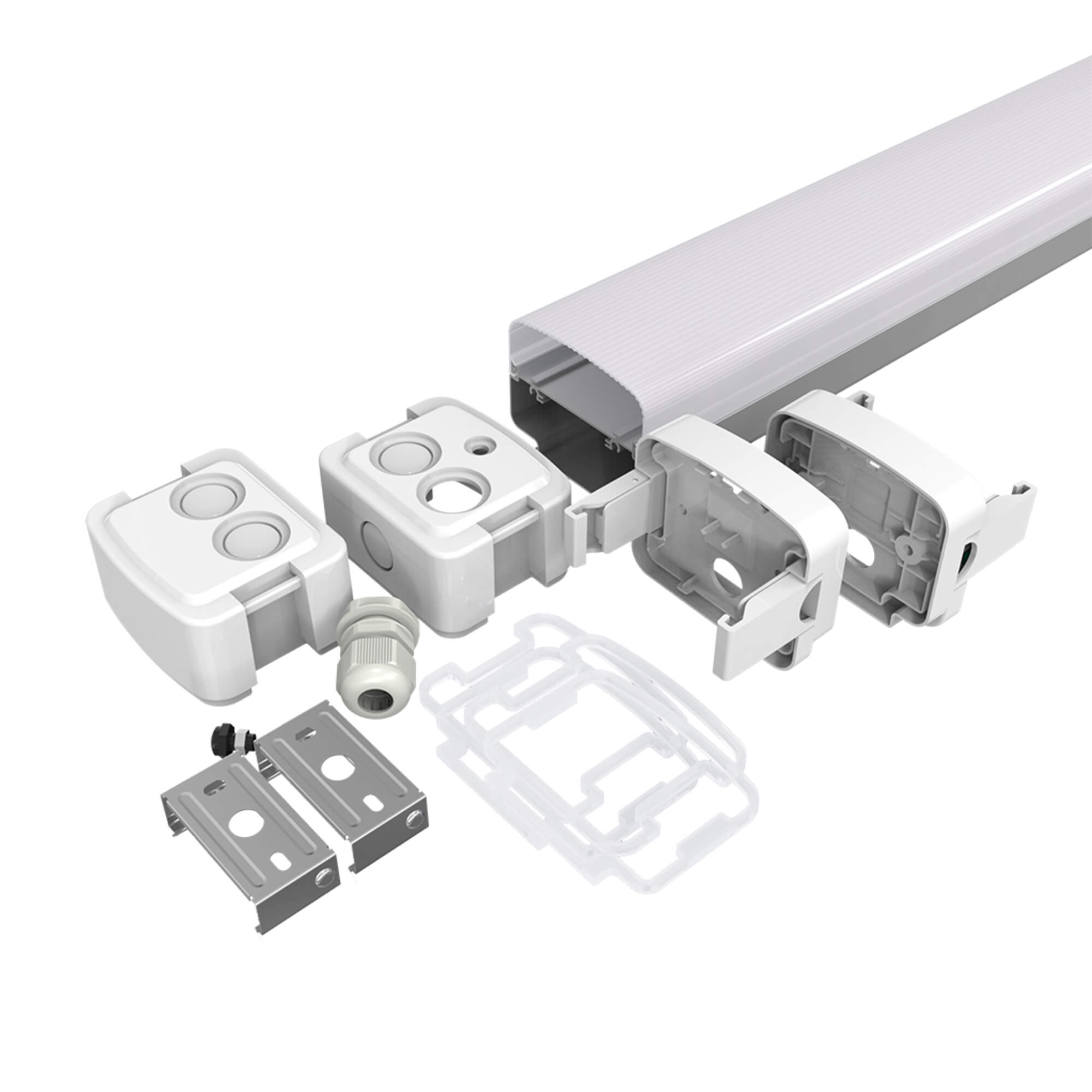

High-efficiency vapor tight LED lighting is specifically designed to meet the demanding requirements of food processing plants. These fixtures are constructed to be resistant to moisture, dust, and other contaminants, ensuring that they can withstand the harsh conditions present in these facilities. Additionally, LED lighting offers superior energy efficiency and longevity compared to traditional lighting technologies, making it a cost-effective and sustainable choice for food processing plants.

The Benefits of High-Efficiency Vapor Tight LED Lighting

One of the key advantages of high-efficiency vapor tight LED lighting is its ability to provide consistent and high-quality illumination in food processing plants. This is essential for tasks such as food inspection, packaging, and processing, where accurate color rendering and visibility are critical. Furthermore, LED lighting produces minimal heat, reducing the risk of affecting the temperature-sensitive nature of certain food products.

Another benefit of LED lighting is its durability and low maintenance requirements. With a longer lifespan and robust construction, high-efficiency vapor tight LED fixtures minimize the need for frequent replacements and repairs, resulting in reduced downtime and maintenance costs for food processing plants.

Enhancing Safety and Compliance

High-efficiency vapor tight LED lighting plays a crucial role in enhancing safety and compliance within food processing plants. These fixtures are designed to meet industry-specific regulations and standards, such as NSF International requirements for food processing equipment. By choosing LED lighting, plant operators can ensure that their facilities meet the necessary lighting standards while also creating a safer working environment for employees.

Furthermore, the advanced controllability of LED lighting allows for customization of lighting levels and patterns, enabling food processing plants to optimize energy usage and create specific lighting environments for different areas within the facility.

Conclusion

High-efficiency vapor tight LED lighting has become an indispensable element in the lighting design of food processing plants. Its ability to provide high-quality illumination, energy efficiency, durability, and compliance with industry standards makes it the ideal choice for these demanding environments. By embracing LED lighting, food processing plants can enhance safety, efficiency, and overall productivity while meeting the stringent requirements of the industry.